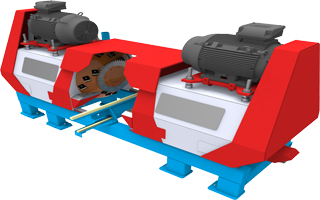

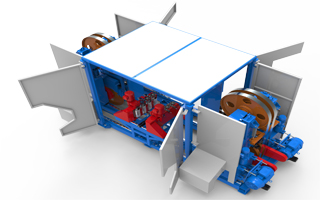

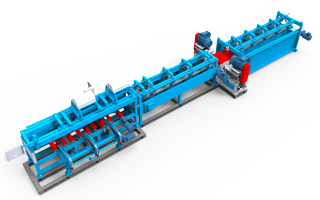

The Smart Sawmill Lines is based on a logic of optimization and complete automation of the process, to obtain the best profitability.

Predictivo

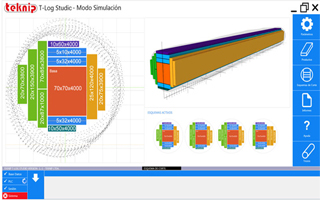

The Smart Sawmill Lines consists of calculating the best cutting solution before each operation, based on a complete measurement of the actual shape and dimension of the wood. And then apply it in a controlled, precise and without the intervention of an operator. This cutting-edge technology is possible thanks to the latest developments in 3D vision, industrial computing and precision mechanics and enables results beyond the reach of traditional sawing technologies, especially for small and medium-sized production units.